Suppose you want to make a

SOLIDWORKS Universal BOM Template for mixed weldments which incorporates weldment

structural members but also sheet or plate and even purchased parts. Suppose

you also want to automate the BOM as much as possible to avoid manually

inputting data and have it update parametrically with changes in your

design… How do you accommodate the three different types of components so

that manufacturing knows which materials to use, and accounting can quickly

add up the material costs?

Using nested IF statements in your BOM columns, you can do just that. For the

BOM above, the only values which require manual input into the parts are Part

Number and Description. Description should already be defined at the profile

level for all of your structural members anyway. None of the cells are being

managed manually at the drawing level, which is as it should be for a

parametric CAD tool.

To do this, just create a weldment using structural members as you would

normally, but make sure that you are creating any sheet metal or plate parts

using the Base Flange/Tab in the Sheet Metal tool instead of a regular

Boss/Base Extrude. We also recommend that if you commonly use flat bar in your

designs that you create custom Weldment Profiles and create those parts as

structural members. Update your cutlist, and give each cutlist body folder a

custom property called PART NUMBER. Description will automatically be filled

out for structural members, and for the plate components; we recommend copying

and pasting the Value/Text Expression from the Sheet Metal Thickness property

followed by your unit of measure and “PLATE”, so that the thickness updates

parametrically with design changes (see below).

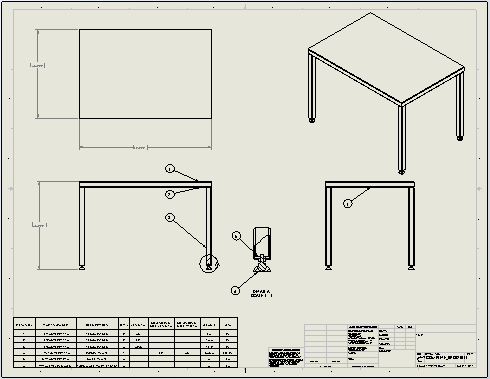

Now, put your model into a drawing and add a

Bill of Materials

using the BOM-standard template that comes with SOLIDWORKS. For BOM Type,

select Indented with Flat Numbering and check the Detailed Cut List checkbox.

Right click the column header for QTY, and insert a column to the right.

Select “LENGTH” from the custom properties drop-down that appears. Repeat this

process to create columns for BOUNDING BOX LENGTH and BOUNDING BOX WIDTH.

Also create two more columns without selecting a custom property (just click

in the paper space when the dialog pops up) and title these USAGE and UM.

At this point, since we created an indented BOM instead of a weldment

cutlist, there will be a top-level row for your weldment file and any other

top-level components (if you are working with an assembly instead of a

single part). The assembly used in this example consists of the main

weldment, threaded base plates and the leveling legs. If you want to keep

the top-level rows in your BOM and give them custom properties, remember

that these are coming from the file->custom properties menu, not the

cutlist since these are top-level components. Also, you can change the “flat

numbering” style we specified earlier to “detailed numbering”. This will

change the numbering scheme to 1, 1.1, 1.2, etc. for the top-level

components and all subcomponents.

If you don’t want these rows in your BOM, you can simply right click on the

row and hide it. Alternatively, you can expand the BOM with a left click on

the three arrowheads on the left and use the minus sign or dissolve command to

properly condense them.

If you have filled out all of the DESCRIPTION and PART NUMBER fields at the

model level, they should be correctly displayed on the BOM. QTY is also

calculated automatically. All of your structural members should have a LENGTH,

and all of your sheet/plate components should have a BOUNDING BOX LENGTH and

BOUNDING BOX WIDTH. (Note that you can use Bounding Box Area, too,

but we prefer length and width because this tells the fabricators the

dimensions for each piece.)

The last two columns are the real secret to the universal weldment BOM

template. Here we will be using a nested IF statement to differentiate between

the three component types. Left click on the column header above USAGE and

click on the summation sign (Σ). This will open the equation editor and we

will be applying the equation to the entire column.

Enter into the equation editor:

IF(‘LENGTH’>0;’LENGTH’*’QTY.’;IF(‘BOUNDING BOX WIDTH’>0;’BOUNDING BOX

LENGTH’*’BOUNDING BOX WIDTH’*’QTY.’;’QTY.’))

This is telling SOLIDWORKS that if the component has a length, it is a

structural member and should calculate total usage based on the length times

the quantity. If it doesn’t, it is either a plate/sheet component, or a

purchase part. If it has a bounding box width, it is a sheet/plate component

and total usage is the length times the width times the quantity. If it’s

neither, it must be a purchased part, and we just report the quantity. We do

something similar for the Unit of Measure (UM) field. The equation for the

Unit of Measure is:

IF(‘LENGTH’>0;”IN”;IF(‘BOUNDING BOX WIDTH’>0;”SQ IN”;”EA”))

Here we are just outputting text values using the same test criteria. When

creating equations in SOLIDWORKS BOMS, it is easiest to use the drop-downs in

the equation editor, but if you want to create them on your own, notice that

Custom Properties are bracketed in forward apostrophes (`Custom Property`), a

Column is bracketed in regular apostrophes (‘Column Name’), and Text is

bracketed in quotations (“Text”).

The last step of course is to save your BOM as a template. Left click anywhere

on your BOM, right click on the black arrows in the top left of your BOM, and

select “Save as”. Save it as a SOLIDWORKS BOM Template (.sldbomtbt) somewhere

other than your install directory (so it doesn’t get written over with the

install of next year’s version of SOLIDWORKS), and it’s ready to use for all

your upcoming weldments.

Hello,

I try to reproduce this cool idea, but cannot solve.

Please, if possible, can send example files?

I SOLIDWORKS VAR in Lithuania :). Can find more about us in http://www.3dcad.lt 🙂

Thanks,

Andrej

Using a similar approach to yours, I have created a fully automated BOM/Works Order system with Excel.

All i do is paste the indented BOM for a full job into the Excel Spreadsheet and it does all the work for me. (Creates Plasma/Press List, Saw list, Bought-In List, Weldment List for manufacturing and Raw material List for purchasing)

Since I am the single employee in the office, it saves me a great deal of time.

My plan is to incorporate job costing in the near future.

Also i plan to translate the spreadsheet to a microsoft access database so i can control inventory and production like an mrp system (Except tailor made an free) 🙂

Have you ever done anything like that?