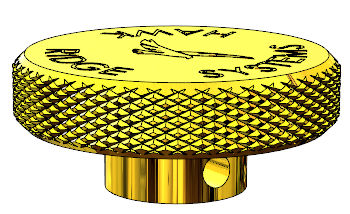

Knurling is a type of surface finish commonly desired on precision tools and

other instances where additional hand grip is required on a machined part. In

practice, knurling is achieved by pressing a dedicated knurling tool into the

rotating workpiece. For this reason, it may not be necessary for manufacturing

purposes to model the knurling explicitly in CAD- many times a simple callout

on a drawing for a knurled surface may suffice.

If it’s desired to have an accurate representation of the product in CAD for

purposes such as photorealistic rendering, however, then it may be necessary

to model the actual knurled geometry. This article and companion video will

focus on a technique to achieve this, and some performance considerations.

|

The first step to creating the knurled surface finish is to create a sketch to

represent the knurl tool profile. In this example, I used a diamond shape

placed with its center coincident to the outer diameter of the cap, and the

width controlled by an angle dimension of 5 degrees. Compare against your

particular knurl tool for specifics.

The second ingredient required is a helical path, which the profile will

eventually be swept along for a cut. To create the helical path, first create

a sketch on the same plane used to create the profile, and

Convert Entities of the outside edge of the cylinder. It is

important that this sketch only contains a single circle.

|

Then, use the Helix/Spiral feature under

Features -> Curves -> Helix/Spiral and select the

sketch containing the circle. Use the Helix option and adjust the start angle

and pitch values to align the Helix with the profile. In this example, the

profile was aligned vertically with the origin, which aligned with a start

angle of 180 degrees. The profile could alternatively be sketched after

generating the Helix to ensure they line up.

Once the profile and path are created, create a

Swept Cut feature using these selections and the “Minimum

Twist” option.

All that is left then is to Mirror and

Circular Pattern the resulting Swept Cut to produce a

representation of the desired surface finish.

|

Generating textured surfaces by cutting away at the CAD geometry is a

computationally intensive process. To help minimize rebuild times there are

two key settings to pay attention to. The first is in the

Circular Pattern options. Use the option for

Geometry pattern which can reduce rebuild times significantly

for repetitive geometry.

The second option is a System Option accessible under the

Performance tab called

Verification on rebuild. Verification on rebuild can

drastically increase rebuild times on geometry such as this as it performs

more advanced geometry checks between each set of faces. It is recommended to

disable it on these types of parts or you may experience excessive rebuild

times.

|

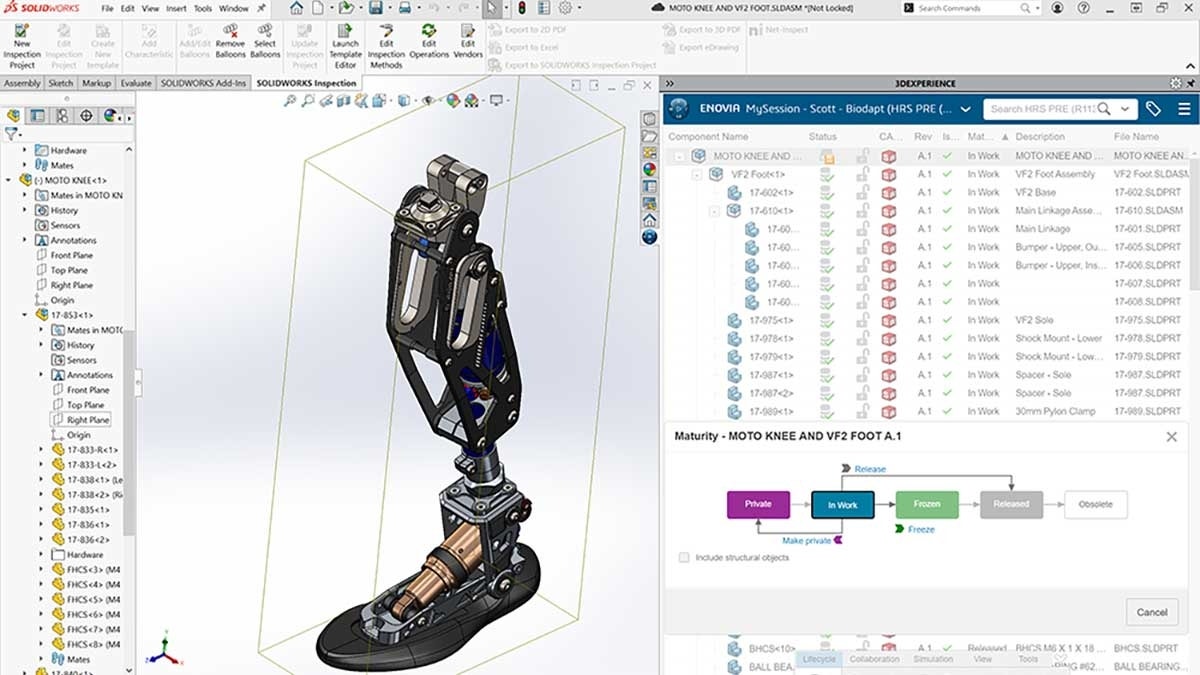

Also consider grouping these detail features together so they can easily be

suppressed. Whenever adding cosmetic detail like this, it is desirable to also

create a “simplified” configuration in case performance ever becomes an issue-

for instance, if dozens of these knurled pieces were necessary for a large

assembly.

There may also be alternative “lightweight” ways to represent the textured

surface, such as using a custom appearance with a Displacement Map. However,

this effect would only be visible in a photorealistic rendering – not within

SOLIDWORKS CAD.

For additional details on how this process can be performed, please check out

this YouTube video or see what else we have on our

channel, check out our

SOLIDWORKS page

or

Get a Quote

for SOLIDWORKS 3D CAD. Don’t hesitate to contact us at

Hawk Ridge Systems

today!

Excellent post. I certainly appreciate this website.

Keep it up!