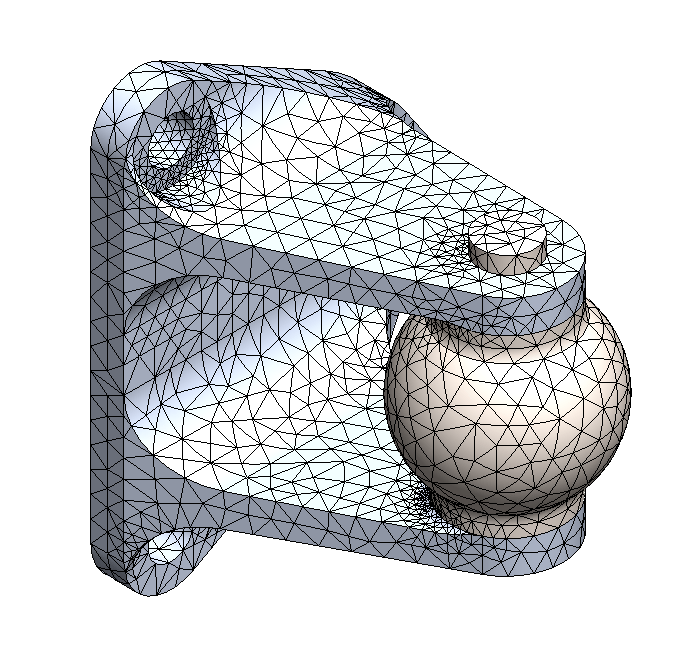

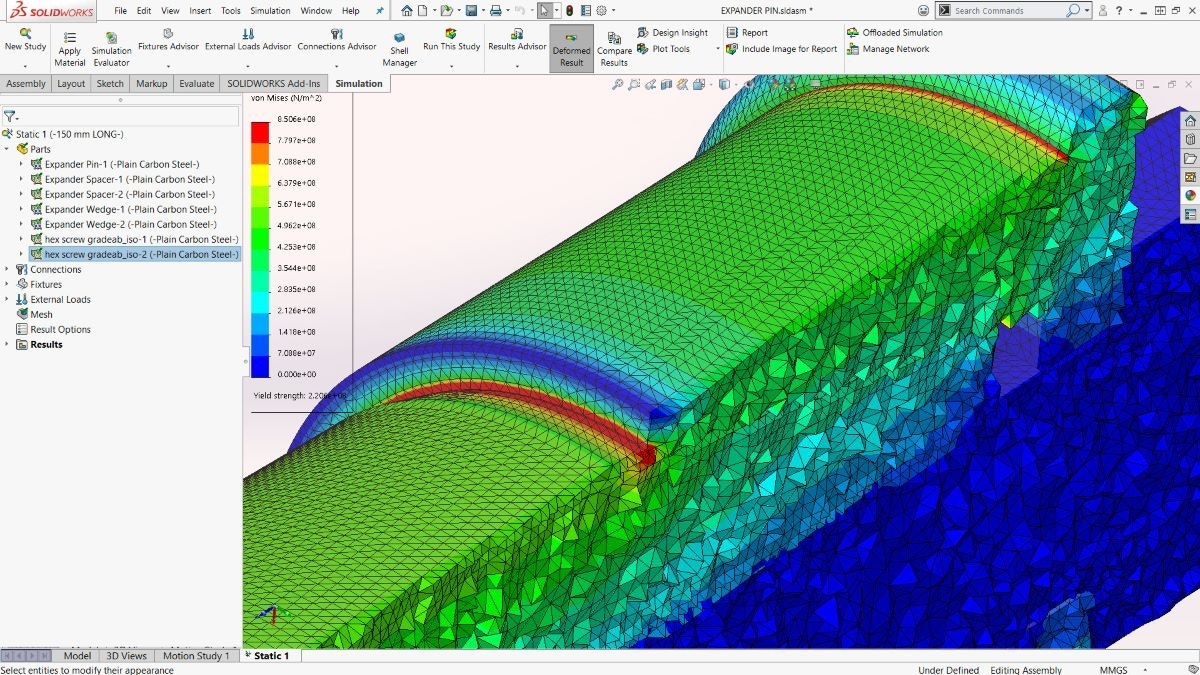

Mesh refinement is an important part of effectively using SolidWorks Simulation, and selective mesh refinement help the user receive high quality results without an unnecessarily large time investment during the solving process. One of the tools that can assist in this process is adaptive meshing, which is a tool used to iteratively vary the mesh settings for your model without active user intervention. SolidWorks Simulation uses two different methods to accomplish this: h-adaptive and p-adaptive meshing. H-adaptive meshing physically adjusts the size of the mesh cell in areas of the model where smaller mesh is needed, while p-adaptive meshing adjusts the polynomial order of the mesh to improve accuracy. This is all done automatically by the software based on a desired accuracy defined by the user. The software achieves the target accuracy by measuring the change in strain energy and stops iterations when two consecutive values differ by less than the given value. First, where are these tools located and how do we activate them? Adaptive meshing is only available for solid mesh models. The setting to activate it is located in the “Properties” window for your simulation study. To access this menu, right click on the top level icon in your studies’ feature tree and select the “properties” option. Select the “adaptive” tab along the top of the properties window. In the top section of the tab will be the options for “none, h-adaptive, and p-adaptive mesh refinement”.

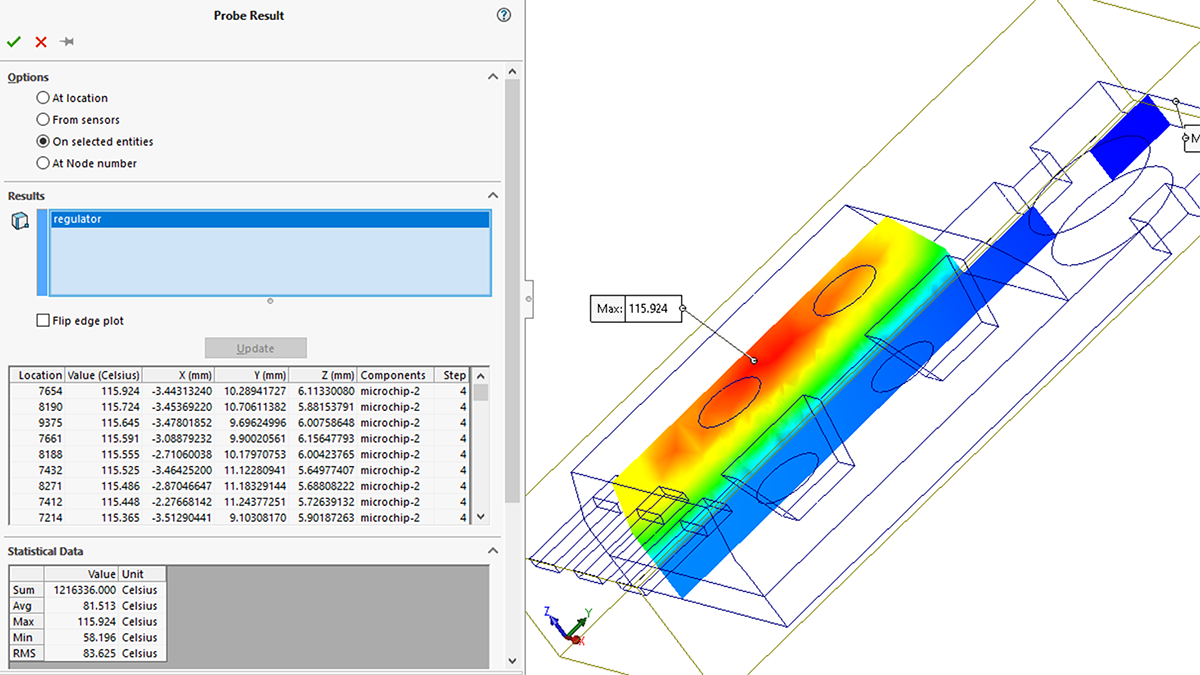

- Target accuracy measures the change in strain energy and stops iterations when the two values differ by less than the stated value; in the provided example of 98%, the iterations would stop when the difference in strain energy between two loops is below 2%

- Accuracy Bias allows the user to balance whether the software iterates to achieve accurate peak stress results in areas where stress concentrations exist, or whether it iterates to achieve accurate global results; with the slider to the far left (Local), areas with stress concentrations will be very highly refined

- The max number of loops controls the allowable number of iterations

- Mesh Coarsening allows the software to intelligently loosen or coarsen the mesh in areas that do not need a highly defined mesh

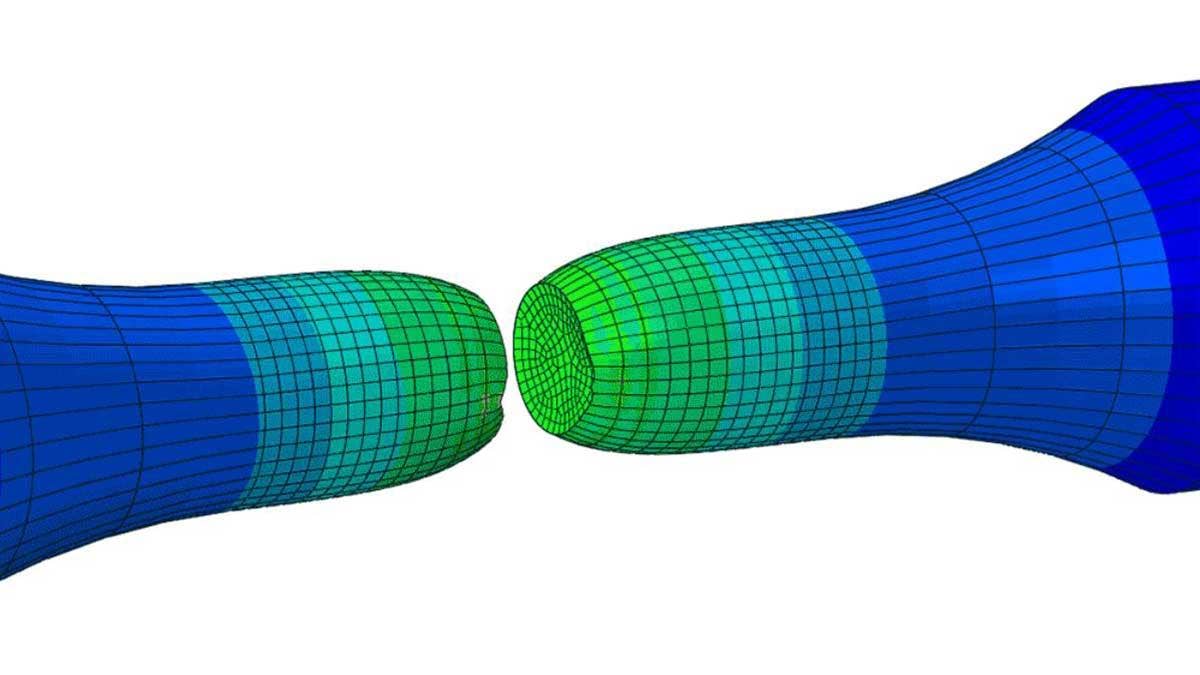

p-Adaptive SolidWorks has two main types of tetrahedral mesh elements. Draft quality elements are first order tetrahedral elements and therefore are linear. High quality elements are second order tetrahedral elements and are parabolic in nature. Using a p-Adaptive mesh setting allows the user to take advantage of mesh elements up to the 5th order.

- Update elements with relative strain energy of 2% or more limits iteration to only areas that meet the specified value

- Starting p-order allows the user to control the starting order of the elements and iteration process

- Maximum p-order stops the process when a certain order of elements has been reached

- The max number of loops controls the allowable number of iterations

Both h-Adaptive and p-Adaptive mesh options can help the user by automatically refining the mesh to achieve more accurate results. These processes are more time consuming than a normal mesh. They are best used for situations in which you are not getting satisfactory results from a standard study or in situations where the accuracy of the result needs to fall within a narrow margin.

Thank you so much for this hard work you’re giving http://solidworksspace.blogspot.com/

The adaptive tab is absent in solidworks 2014.

Where do we go in 2014?

The solidworks 2014 help website doesn’t tell either.

jim – the adaptive tab should still be there in SolidWorks 2014, but you will not see it if the analysis includes geometry and mesh types that are not supported by adaptive meshing – most likely shell or beam mesh would cause this to happen.

Hi

How about irregular models ? Actually I’m trying to simulate an assembly of five instances which are irregular in abaqus or solidworks. Unfortunately I can’t create mesh for this?

Can you help me?

thanks

Mustafa – if you’re unable to create your first mesh on a part or assembly, the adaptive process won’t help. I’d check out some of our material on meshing (go here, and look for a video called Meshing 101 – https://www.hawkridgesys.com/tutorials/solidworks-simulation/), but for a specific problem, I’d recommend connecting with your SOLIDWORKS or Abaqus reseller, and they can take a look at your particular issue.